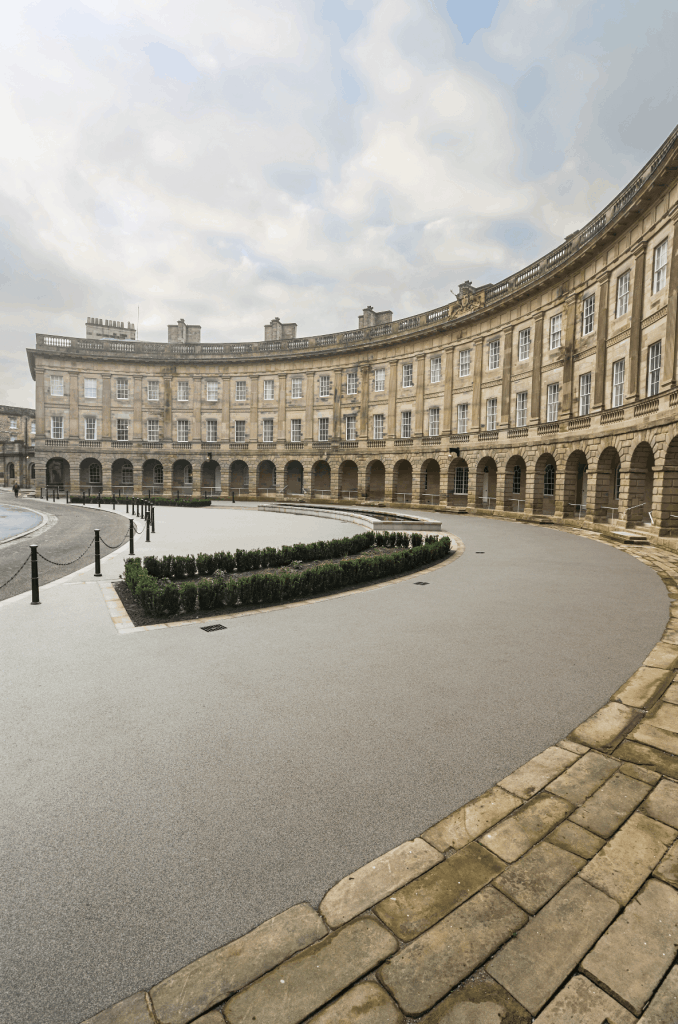

RESIN BONDED GRAVEL

Durable, Textured Surfacing

RESIN BONDED GRAVEL SURFACING

Wetpour is most often installed onto a prepared hard surface, such as stone (MOT) or macadam. The sub-base should be dry, level and compact all over, and any deviations should be such that when a 3m long straight edge is placed in any position on the surface, the gap between the straight edge and the surface shall at no point be greater than +/-6mm.

Bonded Gravel onto Concrete

Bonded Gravel onto Tarmac

RESIN BONDED GRAVEL SURFACINGINSPECTION AND MAINTENANCE GUIDE – DOWNLOAD

All RESIN BONDED GRAVEL SURFACING Surfacing should undergo routine and operational inspection and maintenance in accordance with the recommendations of EN 1176.

The frequency of inspection will vary with the type of equipment used and other factors such as heavy use, levels of vandalism, coastal location, air pollution, age of equipment, location adjacent trees.

If the surface is discovered to be unsafe during inspection and cannot be corrected immediately, the surface should be secured against further use.